The evolution of the transportation industry deeply impacts durability testing processes. Manufacturers introduce multiple vehicle variants, with lightweight designs and or electrified powertrains. At the same time, consumers’ demand for durable products remains high. Durability testing teams suffer from an increased workload under time pressure.

As such it’s essential to streamline your entire durability testing process. This can be done by integrating rugged and reliable data acquisition hardware with comprehensive processing and analysis software. This way, every step of a typical test campaign is handled in the most efficient way, from channel setup and measurements to validation, consolidation, analysis, and reporting.

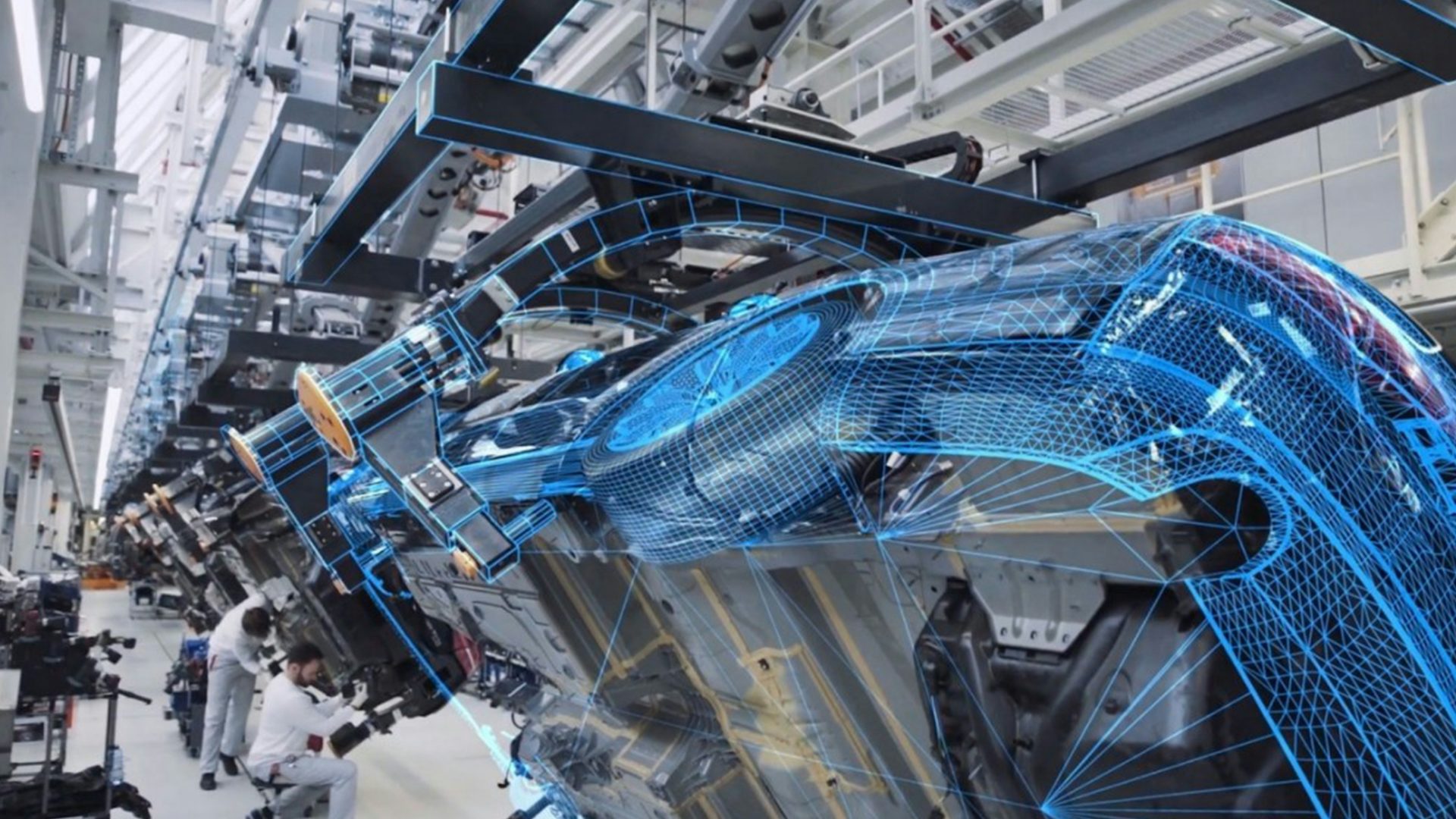

Next to this, it’s key to include measurements in simulation. This way road load prediction is done in hours instead of days, calculating the wheels’ displacement on a virtual test rig based on internal loads. Once validated, durability simulation helps to optimize vehicle performance by predicting the impact of material, geometry, and welding changes.

With Simcenter solutions, you execute your entire durability process in less time, with increased confidence, and fewer errors than ever.

Join us for a 7-session online series and learn how to address durability engineering challenges through Durability Testing and Simulation Solutions.