Vehicle electrification wire harness manufacturing software

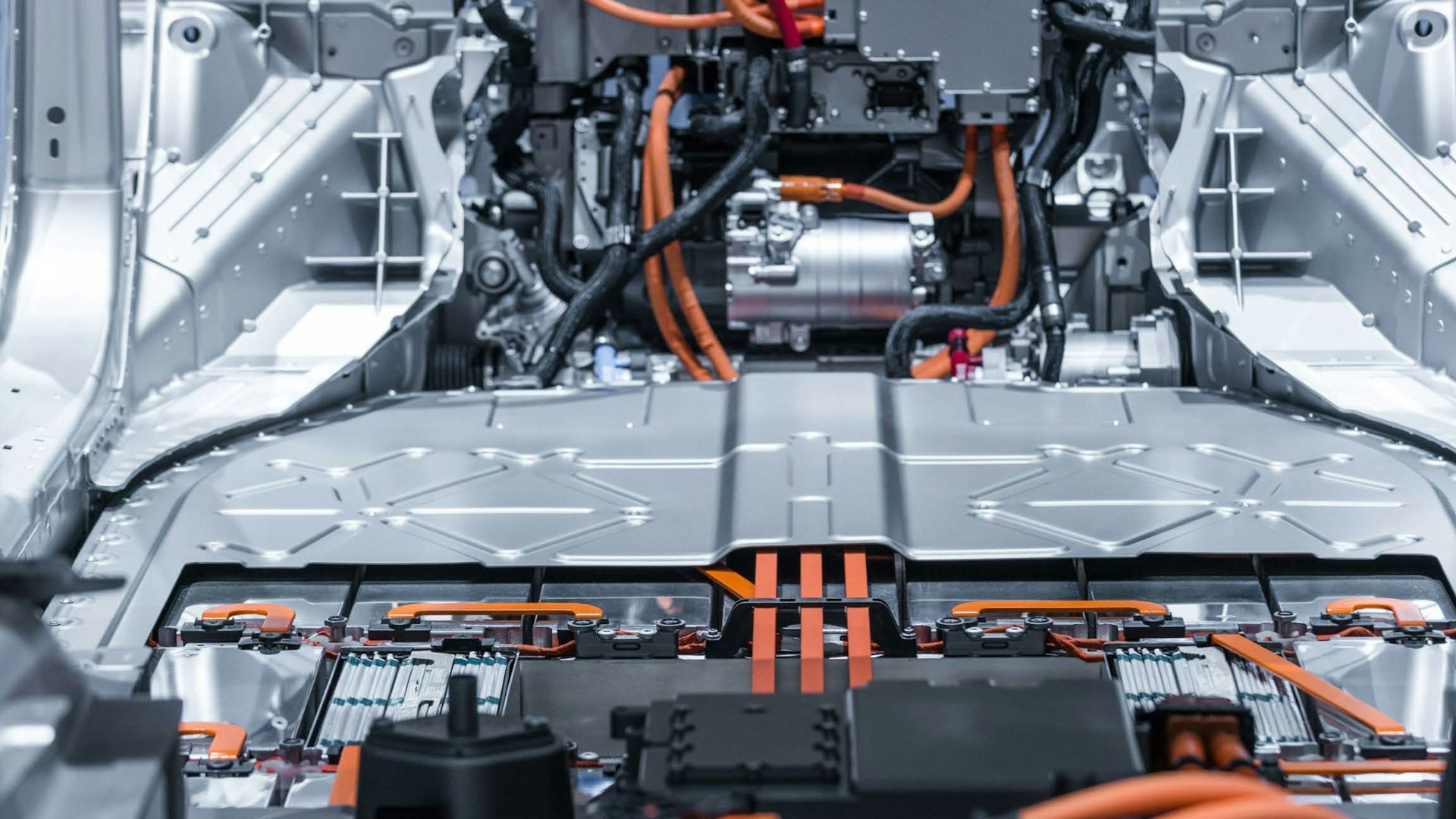

Wire harness manufacturing software supports automotive manufacturers and suppliers overcome the unique challenges due to vehicle electrification. It streamlines the design and engineering processes, enhances manufacturing efficiency, ensures product quality, and promotes collaboration, ultimately contributing to the successful integration of high-voltage and complex wire harnesses in electrified vehicles.

Wire harness design and engineering - Create and optimize wire harness layouts, route wires, and cables, and manage connectors, splices, and other components. Ensure designs meet the electrical and mechanical requirements of the electrified vehicle, optimizing space utilization and reducing manufacturing complexities.

Wire harness design simulation and validation - Validate and analyze the electrical performance of wire harnesses before they are physically manufactured using simulation. Optimize the design and ensure reliability and performance by identifying potential issues early in development, such as electrical interference, voltage drop, and thermal effects.

Wire harness manufacturing process optimization - Facilitate the generation of work instructions, bill of materials (BOMs), and manufacturing diagrams, ensuring an accurate and efficient production. Streamline processes such as wire cutting, stripping, crimping, and assembly, reducing errors, minimizing waste, and improving overall productivity.

Wire harness quality control and traceability - Track the manufacturing process and ensure each wire harness meets the specified requirements and standards. Quality checks, inspections, and testing procedures identify and address defects or deviations, ensuring reliability and safety.

Wire harness design and engineering collaboration - Enable cross-functional teams, such as engineers, designers, and production personnel, to work together efficiently with real-time collaboration. Facilitate information sharing to ensure everyone in the manufacturing process is aligned about the latest design changes, manufacturing instructions, and quality requirements.