DESIGN EXCELLENCE FOR MEDICAL DEVICES

Align for excellence

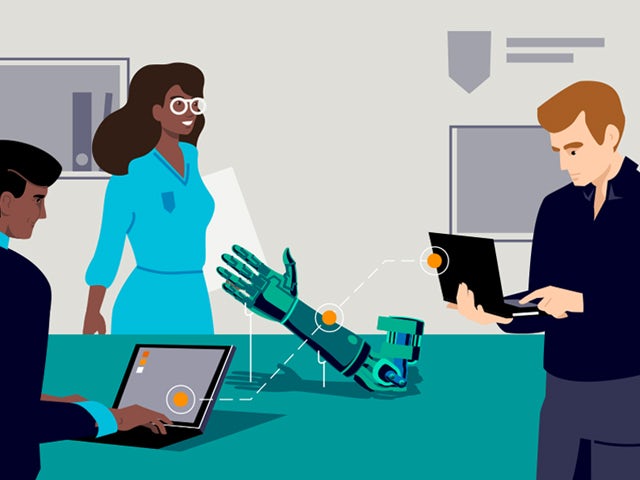

Enhance product development processes by improving collaboration and efficiency.

The market for orthopedic and dental devices is increasingly competitive.

While both consumer demand for personalized products and the technical capabilities to meet them grow, manufacturers are under pressure to innovate at speed – all while meeting stringent, ever-changing regulations and reducing costs.

It can be tempting for individual departments to pile resources behind workflow-specific tools and solutions. But this siloed activity can have the opposite of the desired effect.

Clear organizational alignment is critical. When all teams collaborate around a single source of information, they can innovate at speed while avoiding mistakes, simplifying communications and making smarter decisions.

The Siemens Digital Industries Software portfolio is built around a “digital twin” philosophy, where everyone is working on a single virtual instance of the product.

A suite of collaborative design management software tools and a common hub of stored information enables parallel design activities and easier auditability.

This approach has helped Unlimited Tomorrow to disrupt the pediatric prosthetics industry with TrueLimb, a lightweight, affordable prosthetic limb personalized for the user.

With all the data held in one place, the design can be easily tweaked, improved and scaled up without restarting the whole process. This alignment helps to reduce the cost of a typical prosthetic by 90% and enables the company to deliver the prosthetic five times faster.

Download our executive brief

Learn more

Downloads

To discover what a renewed, holistic focus on design excellence could mean for your business, download our executive brief now.

Executive brief

The business benefits of collaborative design to navigate regulation. Siloed teams working on complex medical device design lead to delays. Learn how Siemens drives efficiency in the creation of safe, effective medical devices.