The purpose of a wire harness is to organize individual wires into a single unit to efficiently transmit electrical power and signals. A wire harness reduces labor time and potential for human error, enabling technicians to fit complex wiring assemblies into small or hard-to-reach spaces.

For example, in some modern vehicles there are approximately 40 different harnesses, comprised of roughly 700 connectors and more than 3000 wires. The bundling of wires and cables into a wire harness simplifies connection to larger components as a single unit for drop-in installation, instead of connecting every individual strand.

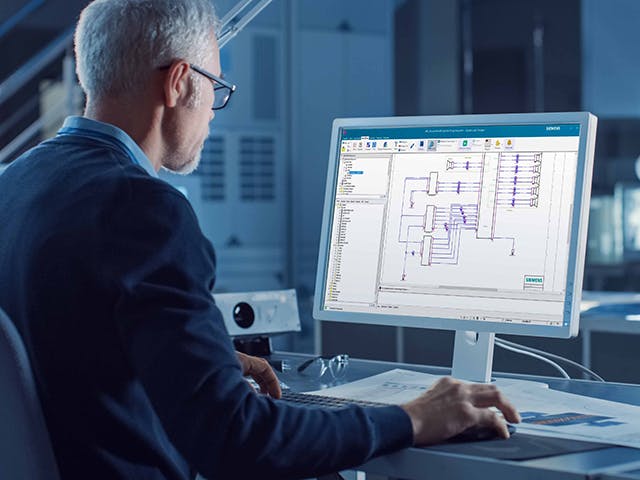

What is wire harness design?

Wire harness design is the process by which an engineer evaluates the requirements of an electrical part of system, given available physical space to create an assembly of wires to deliver power and information as needed. The design must connect all necessary components and not interfere with other systems critical to the operation and purpose of the product.

For example, a wire harness in an airplane must power everything from flight controls to passenger comforts and landing gear. The wire harness design must consider and account for mechanical systems, passenger and crew comfort, weight distribution, plumbing and more to ensure safe and efficient transport.

Challenges in wire harness engineering

Although wire harness manufacturing has been around for more than a century, today's manufacturers face myriad challenges with low margins, loss of tribal knowledge, complex processes, continuous change and stringent requirements for quality and delivery. By implementing model-based workflows, manufacturers can unify previously fragmented design and manufacturing domains by automating data exchange and facilitating cross-domain decisions. Through the integration of design rules that support automation and consistency across the engineering process, tribal knowledge can be captured instead of lost.

Utilize a comprehensive digital twin in the wiring harness design process

Replacing antiquated manufacturing engineering tools and methods while continuing the flow of design data is possible with digital twin technology. This is vital for efficiency and cost-effective manufacturing. As a result, more and more companies rely on a comprehensive digital twin in the wiring harness design process.

Most vehicle manufacturers, for example, have implemented a full lifecycle digital twin to maintain traceability of a vehicle's design, manufacturing and usage processes. With a comprehensive digital twin comprising a validated harness model and a digitized manufacturing process model, companies can transform engineering, costing and manufacturing performance – ultimately boosting profits.