SLS is a powder bed fusion technique for additive manufacturing (AM). It creates 3D objects by using a laser to heat powdered particles selectively so they fuse and become a solid structure.

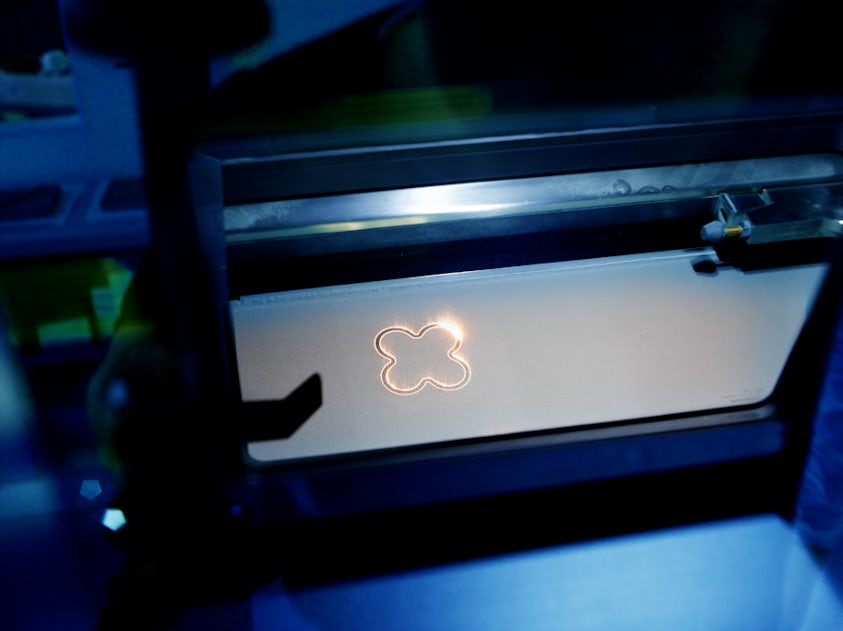

During the sintering process, the material is heated just enough to start atomic diffusion between particles – causing them to bind without actually melting. An SLS machine uses a pulsed laser to sinter powdered particles with enough precision to 3D-print parts with highly complex geometries out of plastic, metal, ceramic and glass.

Because it can easily create intricate shapes directly from CAD data and is compatible with a wide range of materials, selective laser sintering is an extremely versatile technique for manufacturing prototypes and end-use parts.

Related products: NX AM Fixed Plane | NX AM Multi-Axis | NX AM Build Optimizer