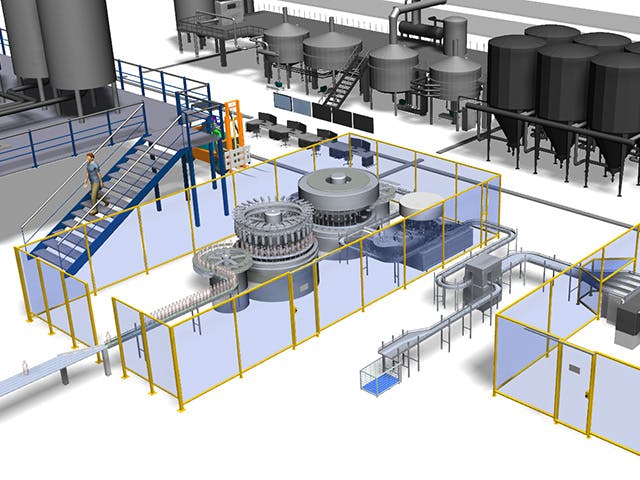

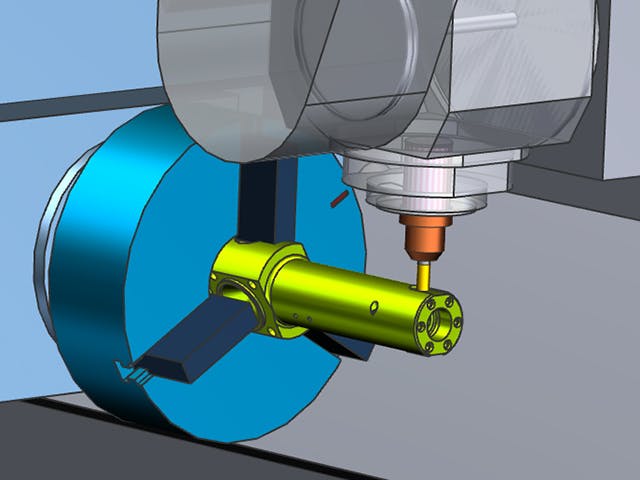

Manufacturing simulation reduces the time and costs that physical testing of a manufacturing system would incur.

Use simulation software to predict the performance of a planned manufacturing system and to compare solutions for any problems discovered in the system's design. This makes manufacturing simulation a significantly competitive capability — allowing manufacturers to test various scenarios before buying tooling, reserving capacity or coordinating other expensive production resources. By using simulation software to determine exactly what is needed, the manufacturer can avoid problems during production while reducing scrap and rework.

In addition to validating all-new means of production early in the product lifecycle, you can apply manufacturing simulation to existing facilities or processes to identify inefficiencies or analyze the impact of introducing new equipment, materials or other changes.

Related products: Tecnomatix Process Simulate | Tecnomatix Plant Simulation | NX for Manufacturing | Solid Edge