The manufacturing bill of materials serves as a master definition that informs the organization what to make, while the bill of process (BOP) provides complementary information explaining how to make the product.

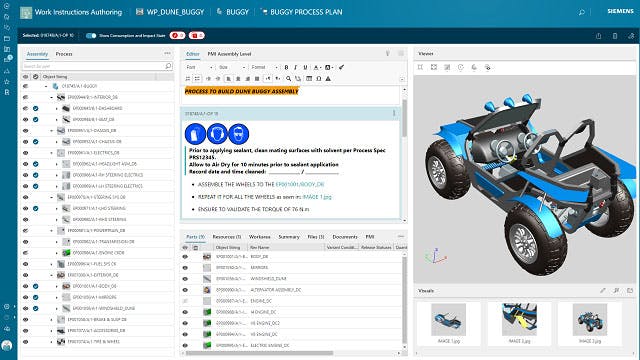

The manufacturing BOM is generated in manufacturing process planning software within a manufacturer's product lifecycle management (PLM) system. As products across many industries have become more complex and include mechanical, electronic and software development, creating the MBOM within integrated PLM software has become essential to ensure accuracy and flexibility.

The manufacturing bill of materials is distinct from the engineering bill of materials (EBOM). However, a modern PLM ensures that all bill of materials associated with a product are defined and managed to be consistent. While the EBOM emphasizes how materials and parts relate to the product's functional design, the MBOM reflects how the materials and parts build a complete product. The EBOM is based on design data, and the MBOM on the EBOM.

Related products: Teamcenter | Manufacturing Process Planning