Electronic work instructions provide complete, enforceable operator instructions. Electronic work instructions software is structured such that operators complete tasks as specified. Electronic work instructions traces both the particular operator and the actions taken. Tasks can be configured to require operator acknowledgment or specific data collection, or create informational history in the manufacturing audit trail. Operators acknowledge each task as it is performed with either a simple click, a specific “yes” entry, or by collecting detailed parametric data. Electronic work instructions software can also require electronic signatures to complete any task.

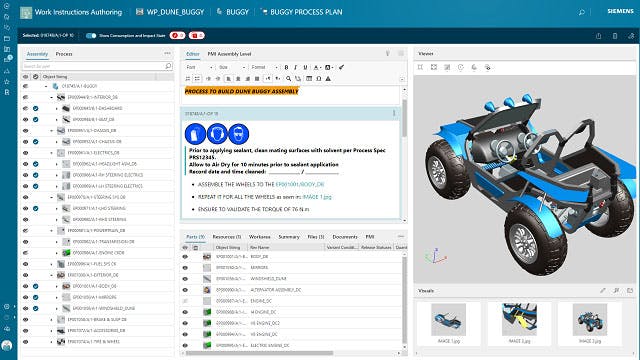

Using a comprehensive suite of 2D and 3D work instruction authoring and viewing applications improves communication of assembly instructions to the shop floor by providing 3D views and up-to-date process steps.

AR in electronic work instructions is ideal for improving the quality and productivity of manufacturing operations that rely on floor personnel to perform critical tasks. These include low-volume production of highly configurable products involving complex and prolonged assembly procedures, as well as assemblies that incur high costs from assembly errors.

With electronic work instruction software, task lists can be configured to be executed in a specific sequence or in any sequence. All mandatory tasks must be completed successfully before the material is moved to the next operation. Electronic work instructions software can configure tasks involving data collection with upper and lower limits that are monitored at the time of data collection.

Electronic work instructions software performs the following functions:

- Guides the operator

- Enforces procedures

- Mandates line clearance

- Collects data and verifies values

- Takes action on exceptions

- Integrates electronic signatures

- Populates the audit trail

In manufacturing planning, engineers can author electronic work instructions for operations under the bill of process (BOP). The manufacturing process planning software links textual instructions to reference parts, resources, and visual aids, including 3D graphical representations, to provide shop floor personnel with accurate and clear guidance.

For operator entry, electronic work instructions automatically generates the form from the task definitions, and the operator enters each value. Once entered or scanned, each value is checked against its upper and lower limits, and an out-of-specification value causes the task to fail.

The electronic work instructions can be configured so that an out-of-spec condition or other process failures automatically initiate actions such as placing the product on hold, routing it to rework or a material review board (MRB), or emailing a message, depending on the configured business rules.

Effective electronic work instruction software is fully configurable to model a wide variety of manufacturing procedures precisely. Task lists may be assigned to a work cell, workstation, or resource (equipment) via electronic procedures. If the electronic work instructions software is modular, tasks and task lists can be defined once and used in multiple procedures. Changes to a task list are automatically applied to all occurrences on the task list.

Tasks in electronic work instructions are easily modified as manufacturing processes change. Electronic work instructions software is designed with revision control capabilities to ensure operators use the correct revision of instructions.

Line clearance is easily enforced by electronic procedures. “Start process” and “end process” tasks ensure that only one unit, lot, or batch is in process at a work cell.