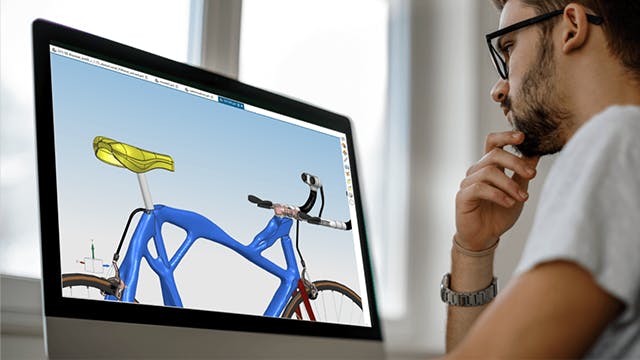

Design simulation helps manufacturers verify and validate the intended function of a product under development, as well as the manufacturability of the product. The word “simulation” is often used as the generic term for computer-aided engineering (CAE). Several design simulation approaches have become standard components of product development in many industries, and they continue to grow in importance as inexpensive, faster computers and affordable, easy-to-use design simulation software allow users to address new technologies and applications.

Simulation models are mathematical equations representing the system's behavior in a physical domain of interest. The complexity of mathematics depends on the availability of data and varies in the function of the application and the design stage.

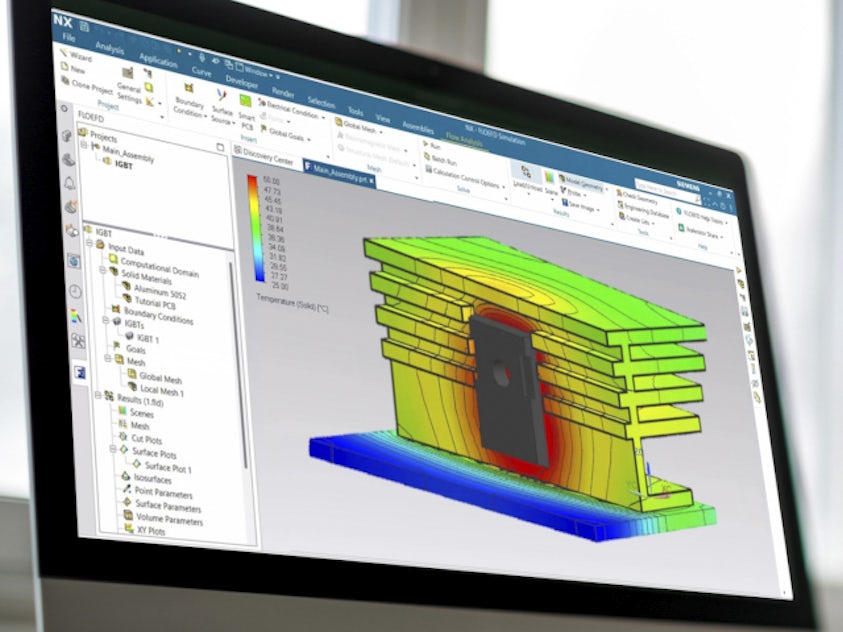

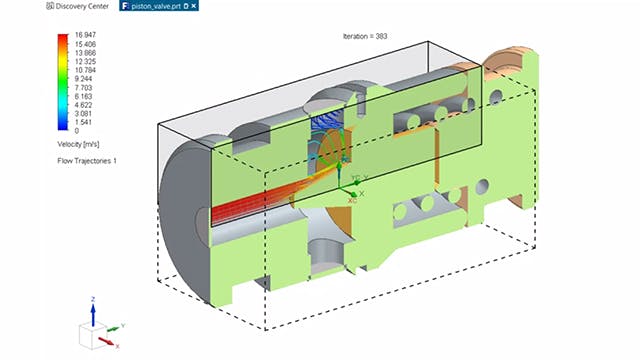

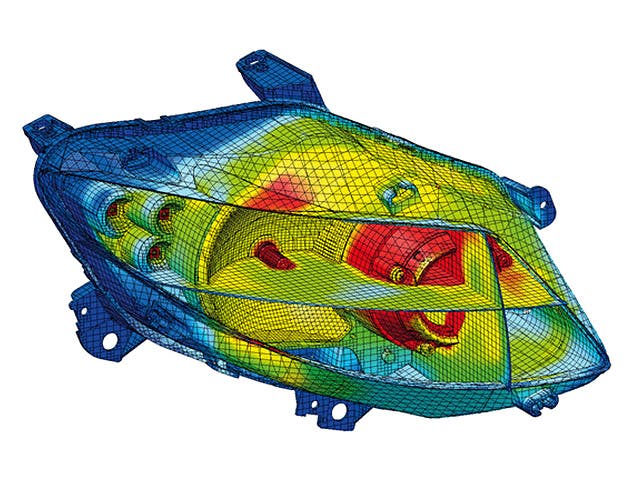

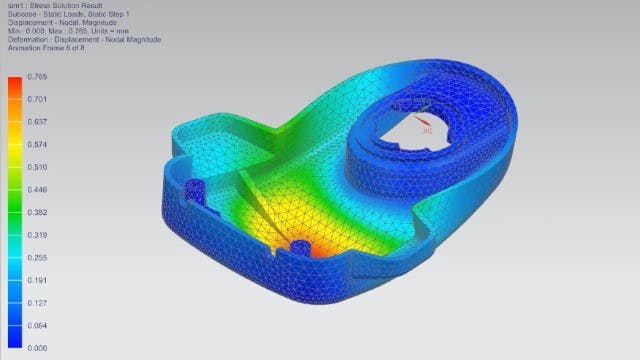

In early development, typically more simple system representations use analytical assumptions and verify the interaction between several physical aspects on a concept level. In late development stages, typically very complex, application-specific models are used for validation and refinement. The applications can cover aspects such as structural behavior, acoustics, structural dynamics, thermal and flow analysis, fuel economy, control development and much more.

Related products: NX | Solid Edge | Zel X | Simcenter FLOEFD