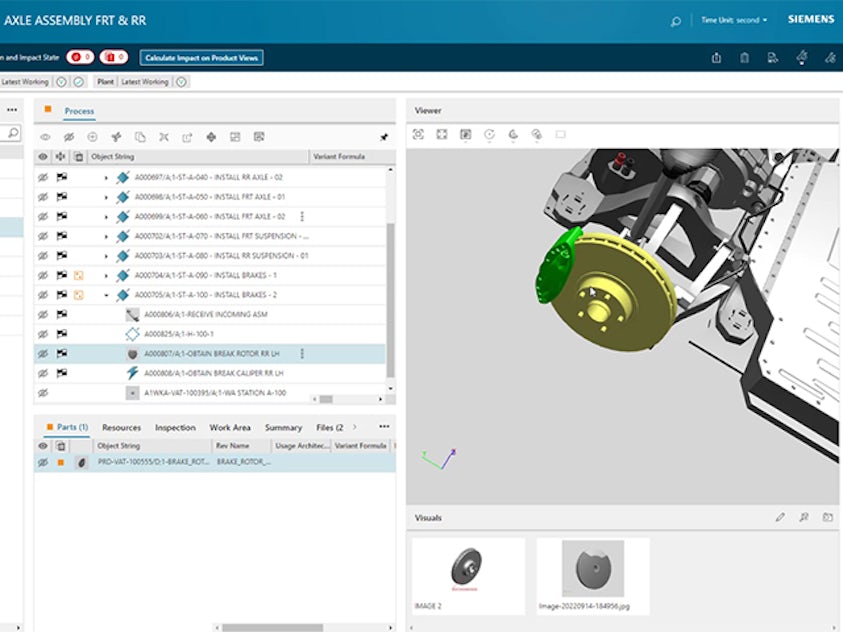

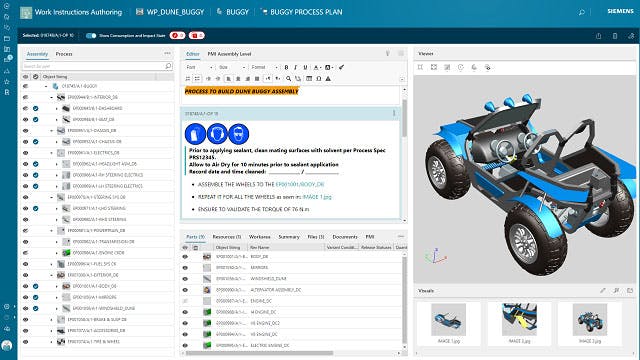

A bill of process (BOP) details the planned production approach for a specific product. It presents a best practices template for manufacturing each finished good. The bill of process lists production line configurations, tools, machines, and equipment needed to make the product. The bill of process also contains the electronic work instructions (EWI) that explain how to make it. bill of process information complements the manufacturing BOM (MBOM), or manufacturing bill of materials, which lists the materials and components needed to make the product.

Prior to the development of product lifecycle management (PLM) software, the bill of process was generated manually on paper or in isolated electronic documents. Any changes to a product and/or its manufacturing processes necessitated manual updating of the bill of process, manufacturing bill of materials, and electronic work instructions – an inefficient and error-prone process that lacked both visibility and scalability.

Modern PLM systems generate a bill of process within integrated manufacturing process planning software. This integrated capability allows changes to be reflected in the bill of process rapidly – and communicated immediately to the shop floor for implementation. The bill of process communicates the production plan to the manufacturing operations management (MOM) solution, especially the manufacturing execution system (MES), to guide and orchestrate the implementation of the plan.

Related products: Teamcenter Easy Plan | Tecnomatix