Additive Manufacturing Technologies & Processes

Additive manufacturing can be accomplished using various techniques like Binder Jetting and Laminated Object Manufacturing, but the technologies below are the most frequently used for 3D printing.

Material Extrusion (FDM, FFF)

This process uses a spool of material (usually polymer-based) and a heated deposition head. The head melts the filament to extrude the material in a long stream. FDM is the technology used in most low-cost desktop printers due to the affordability of the parts and readily available materials in filament/spool form. Software for multi-axis FDM was pioneered by Siemens and our partners in our NX solutions. Our solution has been tested and improved over several generations and is the most robust platform for these types of operations.

Stereolithography (SLA)

Stereolithography is one of the oldest additive manufacturing (AM) processes and uses liquid resins to create 3D objects. In most cases, the resins are cured using ultraviolet light. SLA printers are somewhat different from other technologies because the part is printed in the –Z direction. This means that once solidified, each layer of the printed part is pushed down into the resin rather than being built upwards, as with most other processes.

Powder Bed Fusion (DMLS, SLS, EBM)

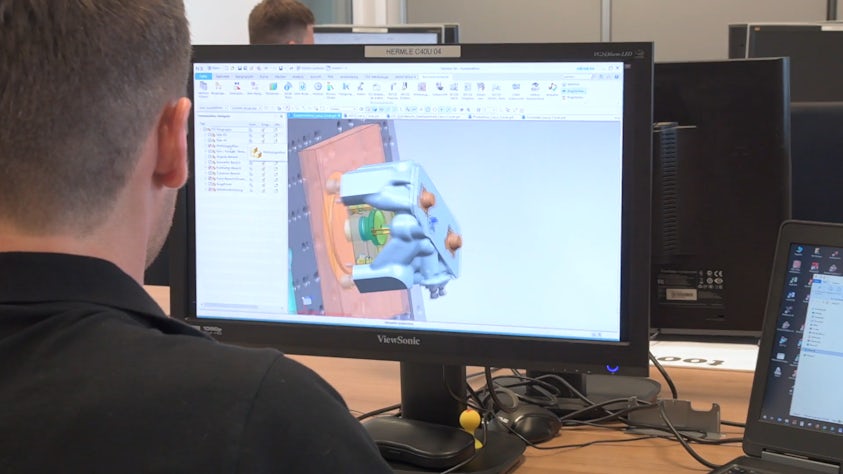

Powder Bed Fusion is a term that describes many additive processes, including metal additive manufacturing. All involve a bed of powdered material that gets fused layer-by-layer in a planar fashion. This is done with multiple material types, both plastic and metal. A multitude of technologies are used to fuse powder material. The integrated nature of Siemens NX allows you to perform necessary tasks, such as 3D nesting of parts in the build tray or construction of support structures for PBF printing without data translations or using external software packages. The advantage to this is that as your part geometry changes through revisions, those downstream operations are automatically updated with little user interaction, saving large amounts of design and setup time.

Binder Jetting

Binder Jetting is a category of additive manufacturing (AM) techniques that use inkjet-style printheads to selectively deposit a liquid bonding agent onto powdered material to form solid, 3D objects. Because the powder molecules are bound together by an adhesive chemical reaction instead of melting or sintering from applied thermal energy, binder jetting techniques are distinct from powder bed fusion techniques.

Material Jetting

Material jetting is an additive manufacturing (AM) process in which droplets of liquid resin are selectively deposited via inkjet-style printheads and solidified by ultraviolet (UV) light exposure to build a solid 3D object. Material jetting is considered one of the most precise methods of additive manufacturing. Capable of printing in layers less than 20 microns thick, material jetting is known for building CAD designs with fine details, high accuracy, and smooth surfaces.