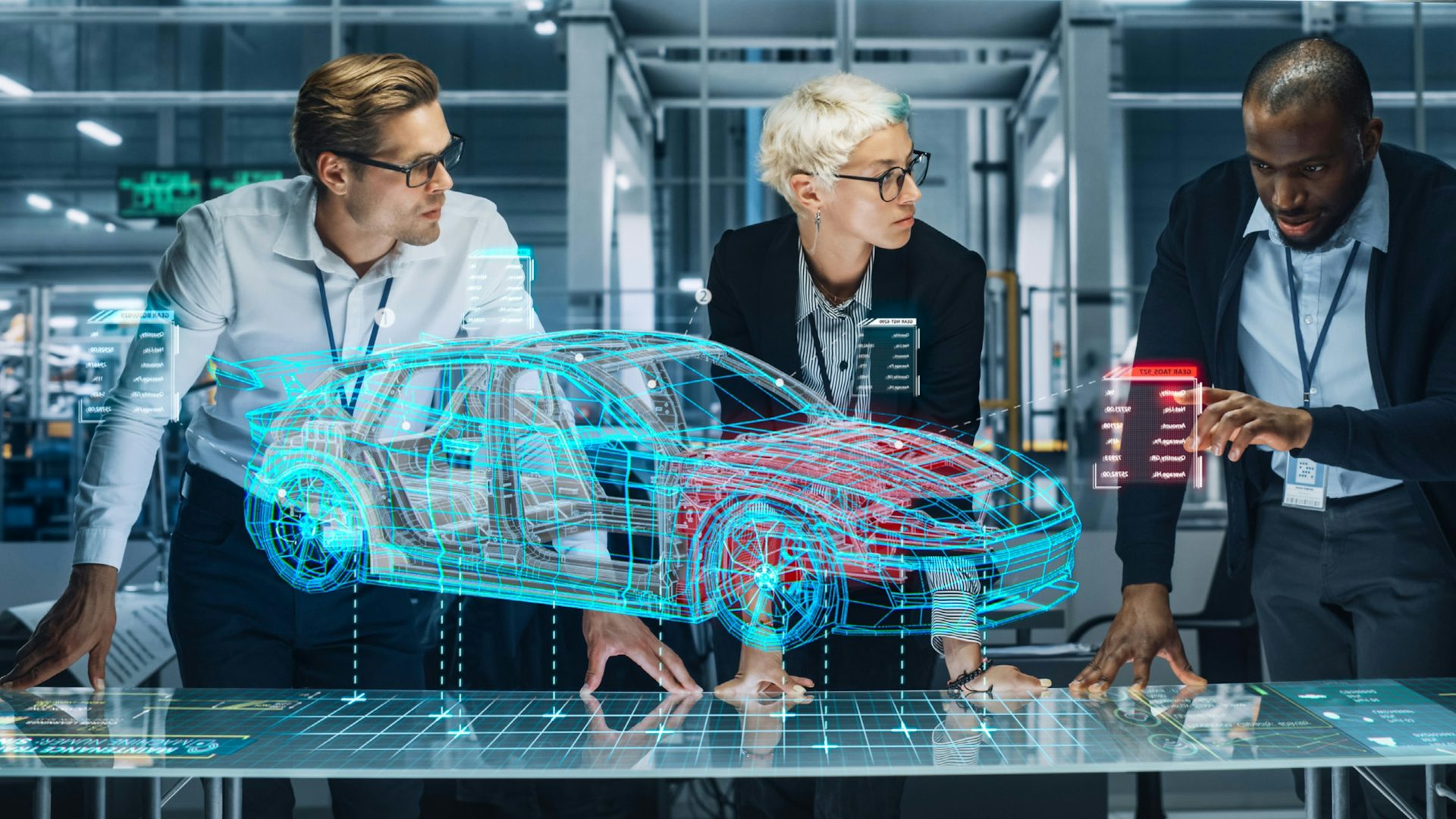

Adopt MBSE in vehicle development

With the advent of hybrid and electric vehicles, the complexity of engineering and systems management continues to grow exponentially. For vehicle manufacturers to continue developing their products at the same pace and a competitive cost, it will take a process revolution supported by an integrated model-based systems engineering (MBSE) approach. By adopting an MBSE approach in vehicle development, automotive manufacturers and suppliers can manage product complexity to deliver the right vehicle on time, every time.

Improved collaboration: MBSE allows for greater collaboration between different teams involved in vehicle development. Using a common modeling language, engineers from different disciplines can work together more effectively, reducing misunderstandings and errors.

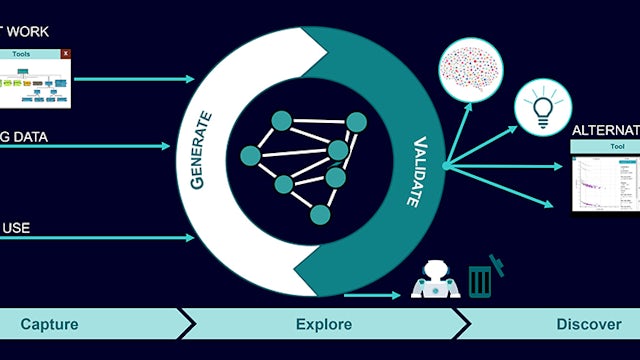

Better requirements management: With MBSE, requirements can be captured and tracked more effectively, ensuring they are met throughout the development process. This helps to reduce the risk of costly design errors and project delays.

Increased design efficiency: MBSE provides a more efficient way to design and develop complex systems, allowing faster and more accurate design iterations. This can help reduce development time and costs.

Enhanced system performance: By simulating and analyzing different scenarios using MBSE, engineers can optimize system performance and identify potential issues early in the design process.

Improved traceability: MBSE allows for improved traceability between requirements, design, and testing, ensuring system performance is optimized, and compliance with regulations is achieved.