How can you accelerate component manufacturing?

Component manufacturers must leverage integrated engineering software throughout the product lifecycle to quickly navigate industrial machinery changes. With our solutions' powerful digital capabilities, your organization can successfully balance quality, cost and energy requirements to drive consistency in new product introductions, all while scaling your designs and accelerating time to market.

Optimize your component manufacturing process

Enhance knowledge sharing and standardize processes across departments to drive greater collaboration and alignment on new product development. Increase production while reducing costs, time and wasted resources.

Learn what our customers are achieving using our solutions.

Reduction in project execution time

Increase productivity, reduce project execution time by 20% and report fewer errors using NX and Teamcenter. (Burckhardt Compression)

Projects in target costing

Create reliable cost comparisons and double the amount of projects processed in target costing using product cost management software. (Festo)

Document duplication

Eliminate document duplication. Manage product development from the initial order to the delivery of its complete BOM to an ERP system. (Gate)

Improve the engineering process

Leverage an integrated system that combines the most critical solutions for rapid product design, development and delivery.

Explore the three key areas of NPI for component manufacturing. Our solutions are developed to meet your needs in each area:

Discover novel approaches to facilitate optimal design in a dynamic and streamlined setting. Rapidly develop a 3D digital twin for visualizing, sharing and validating new product designs. Ensure traceability and compliance while accelerating product development.

- Balance and verify internal requirements against changing customer requirements

- Accelerate time to market by using a digital twin for improved visibility across teams

- Visualize the impact of product variability on cost and sustainability

Product development lifecycle

Leverage a fully integrated suite of software tools that bring all your project requirements, configuration and change management into a single location. Use this consolidated view to produce tailored product variants that align on requirements and control material costs.

- Standardize and automate processes for faster turnaround

- Collect and reuse valuable data to save time, reduce costs and improve quality

- Create customized product variants that control costs and increase profitability

Manufacturing cost and efficiency

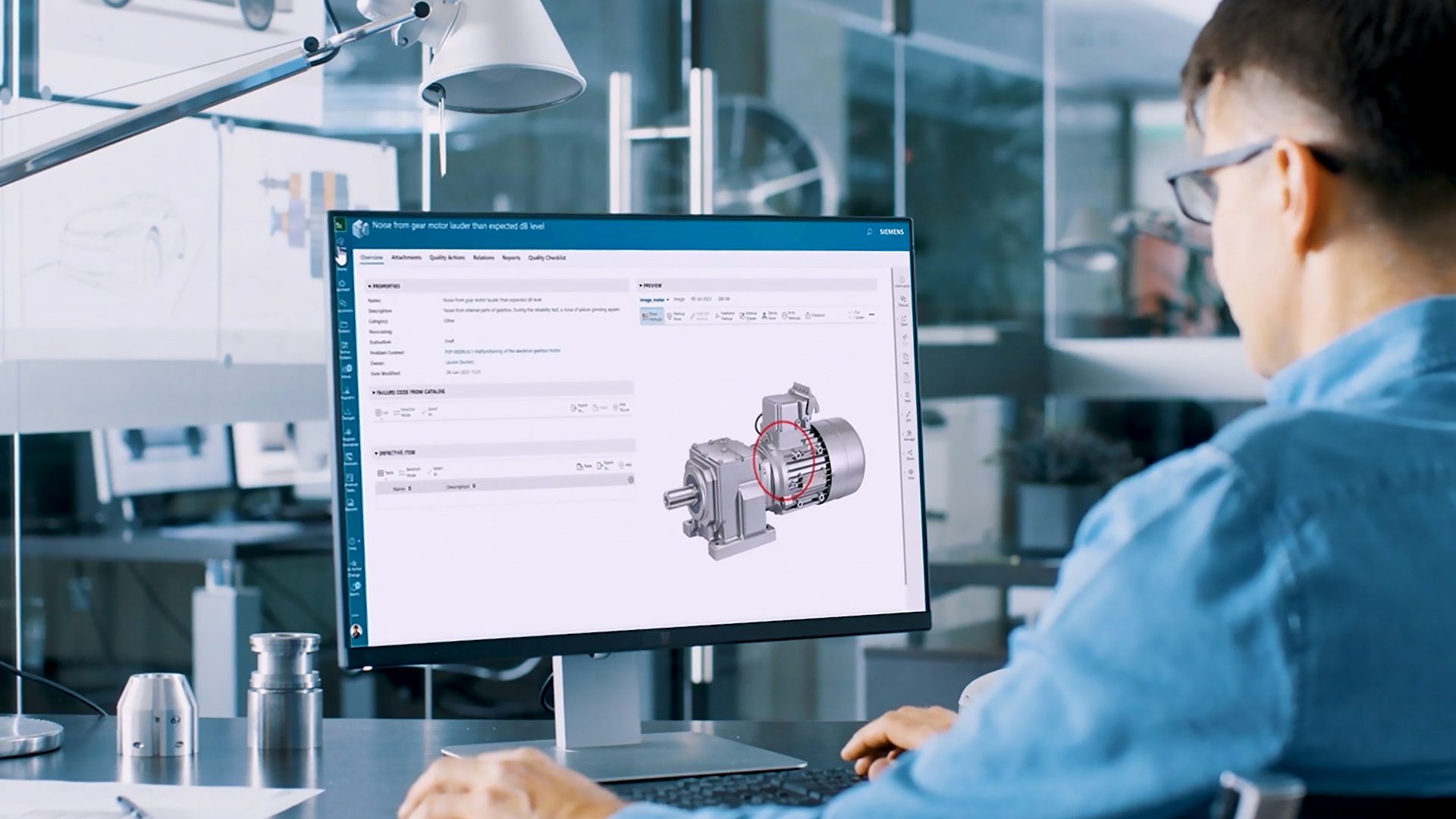

Bring your quality management system (QMS) and product lifecycle management (PLM) process together to create an end-to-end solution. Use modular design tools to develop, configure and scale consistent products, generating a new level of quality through product standardization.

- Achieve quality goals through every phase of the product lifecycle

- Develop consistent, high-quality products with drag-and-drop tools

- Improve product reliability, generating repeat business

Accelerate component manufacturing with us

Discover how our customers are transforming their component manufacturing processes with our solutions.

Ensure early design accuracy

Make correct design decisions earlier in the process and complete complex designs faster. (Werner Weitner)

Enhance operational efficiency

Achieve global control of the product development process and significantly increase operational efficiency. (Bonfiglioli)

Create optimized CAD geometry

Achieve optimized CAD geometry of mechanical components. (Studio Tecnico Zocca)

Marquardt Group

Marquardt Group enhances product costing processes using Teamcenter

Company:Marquardt Group

Industry:Automotive & transportation, Electronics, Semiconductor devices

Location:Rietheim-Weilheim, Germany

Siemens Software:Teamcenter, Teamcenter Product Cost Management

The Teamcenter product costing solution provides better transparency, more precise cost information and was well accepted by all departments and project teams.

Explore our resource library

Refine and perfect new product introduction processes and gain higher returns.

Solutions to accelerate new product introduction

Comprehensive digital twin

Consolidated product data

Integrated quality and manufacturing

Product cost management

Requirements and verification management

Performance engineering

Frequently asked questions

Learn more

Watch

Video | Perfect product launches for higher returns

On-demand webinar | Accelerate design engineering with CAD and the cloud

Video | Benefits of PLM for machine builders

Listen

Podcast | Digital Transformation for Industrial Machinery

Podcast | Executable Digital Twins: A Smartwatch for Machines

Podcast | Breathing Life Into the Digital Twin with Daniel Reed at MxD

Read

Ebook | Accelerate new product introduction with the right digital tools

Case study | Identifying and specifying target costs with Teamcenter

Infographic | Improve time-to-market and manufacturing productivity