Digitalization is changing marine industry trends and competitive advantages. To stay competitive, companies use digitalization to optimize existing fleets and manage resources and energy consumption. Becoming fully digitalized also enhances team productivity and reduces overall product lifecycle costs, enabling a faster time-to-market delivery. But how?

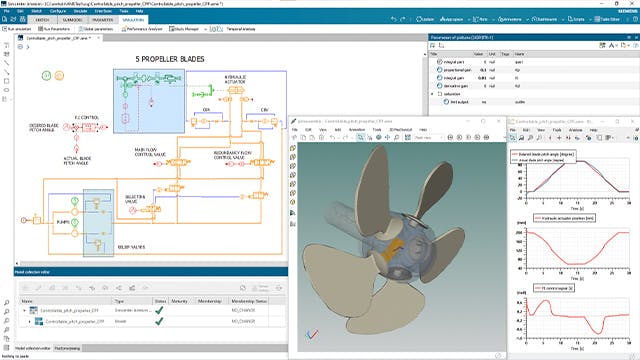

It is essential to introduce an integrated virtual simulation toolkit to maritime engineering as it serves as a single source of truth in your digital journey, enabling the user to push the boundaries of vessel design.

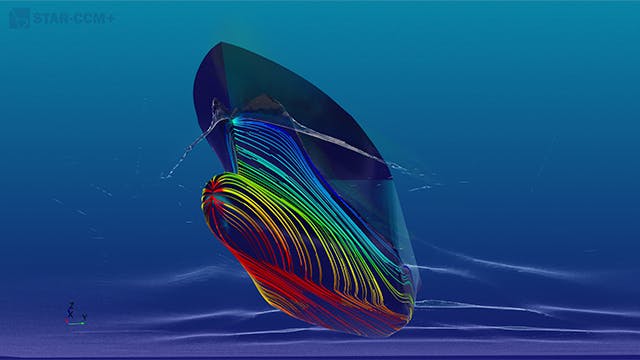

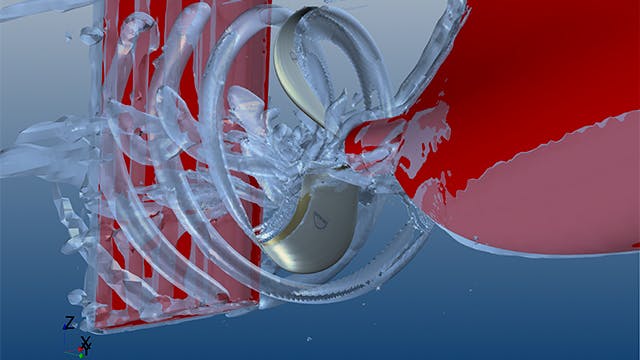

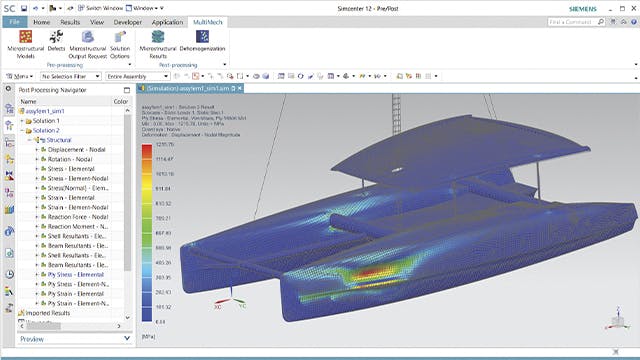

A holistic digital twin can be used to support engineering efficiency when taking a conceptualization to detailed design. Digitalization can help connect the physical and virtual world, from initial to production design, maritime automation systems or engineering and consultancy services to support deployment. A multiphysics approach is key to integrating hydrodynamics, structural integrity, propulsion systems and environmental considerations.