Aby bylo možné splnit požadavky a strategii Mezinárodní námořní organizace (IMO) týkající se dosažení nulových emisí skleníkových plynů, zaměří se průmysl na několik ukazatelů výkonnosti, které představují nové výzvy v oblasti návrhu a inženýrství.

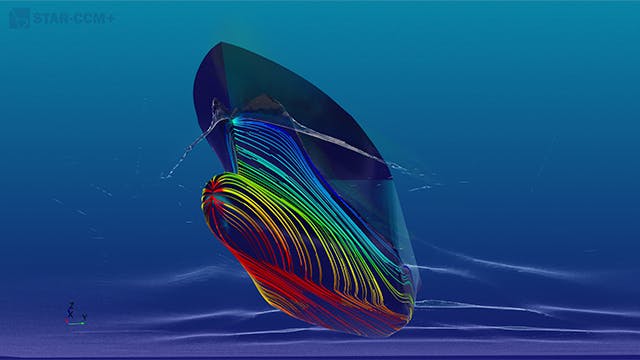

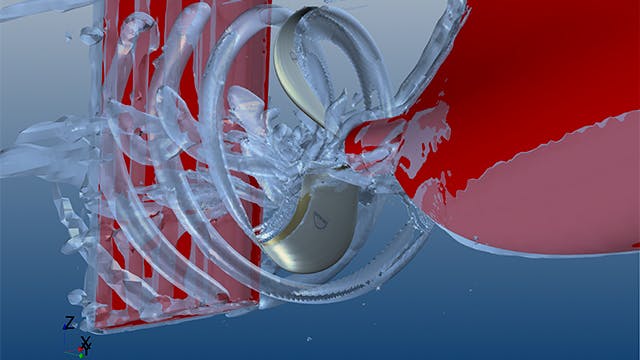

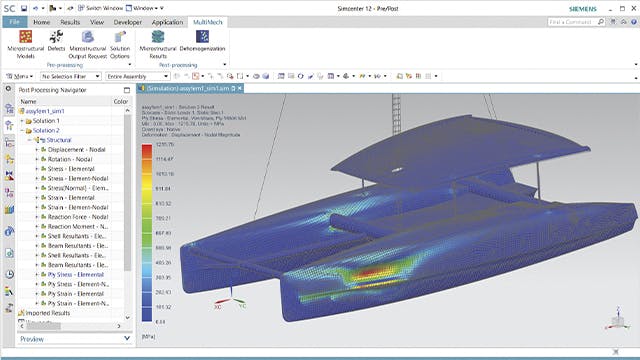

Pomocí simulace mohou námořní architekti a inženýři vytvořit digitální dvojče a virtuálně znázornit loď, předpovídat její výkonnost a zkoumat dopad změn v rané fázi návrhového cyklu v reálných provozních podmínkách. Tento virtuální přístup zefektivňuje hledání energeticky nejefektivnějších řešení a urychluje proces návrhu a modernizace. Jakmile je loď uvedena do provozu, digitální dvojče také těží z vlákna zpětné vazby k datům, například ze zkoušek na moři a profilů misí.

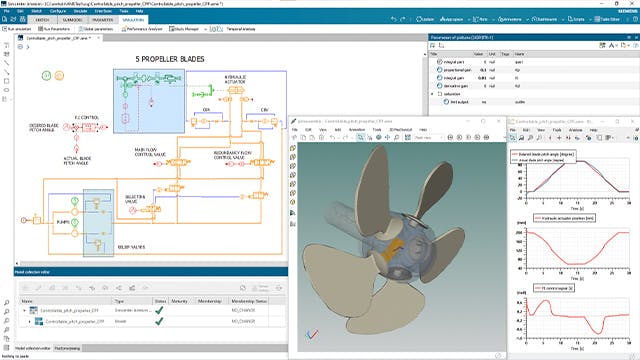

Klasifikační společnosti jsou prvními uživateli simulace pohonu a uznávají tento integrovaný přístup pro účely poskytování cenných a informovaných poznatků o možnostech pohonu s různými kombinacemi paliv. Majitelé lodí si začínají uvědomovat hodnotu vlastních funkcí pro analýzu, pochopení a úpravu výkonnosti jednotlivých plavidel nebo flotil. Vyhodnocují různé konfigurace pohonu a určují tu nejefektivnější.