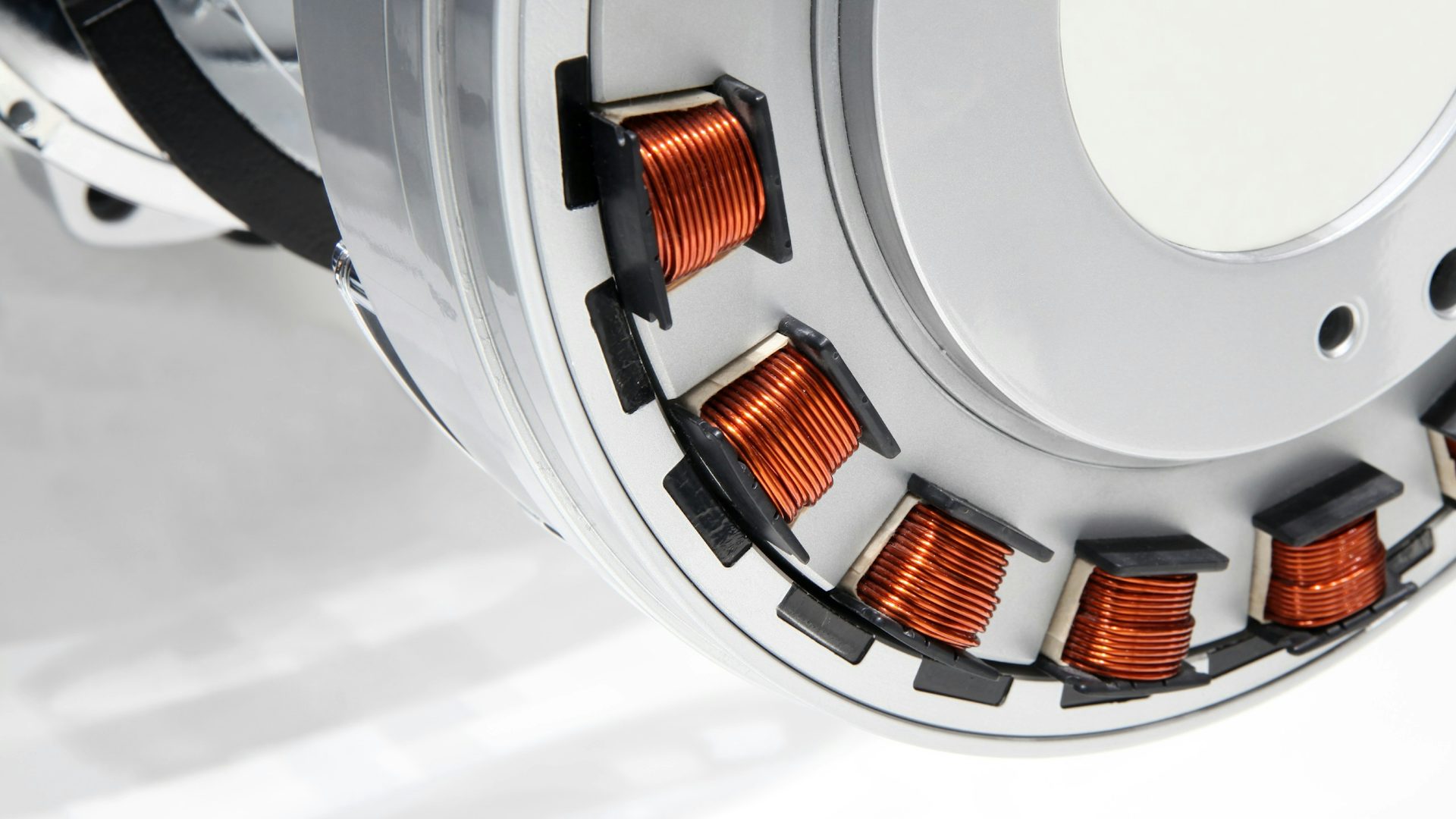

Automotive OEMs and suppliers are moving towards fully integrated electric drive systems, often referred to as e-drives or e-axles. They are facing challenges concerning operational excellence, cost reduction, and time-to-market. Our e-drive solutions for enable effective collaboration between different engineering disciplines, sub-system integration throughout the development process, and acceleration of electric drive systems development from component design, packaging, and performance to vehicle integration.

Effective collaboration between different electric drive systems engineering disciplines

Our Simcenter portfolio offers a connection between all areas of electric drive systems engineering, allowing you to assess how motor sizing and design impact the entire vehicle. The Simcenter portfolio enables us to create an ecosystem for electric drive systems, electromagnetic, thermal, mechanical, and acoustics engineers to collaborate within a single environment where all aspects of engineering design, analysis, and testing are progressed.

Reduce the risk of e-drive NVH issues late in the design process

Addressing e-motor noise, vibration, and harshness (NVH) early in the development cycle is vital for hybrid and electric vehicles, and e-drive manufacturers are looking for solutions to make the perfect trade-off between efficiency and NVH performance. We provide insights into finding the perfect balance between efficiency and NVH and enable you to reduce the risk of encountering e-drive NVH issues late in the design process.

Manage e-drive sub-systems integration throughout the development process

Maximizing transmission system efficiency while minimizing weight and combining it with the rest of the drive within packaging limits is another significant challenge for electric drive systems. We can help you assess gear contact stresses, bearing forces, and shaft flexibility so that noise and vibration from the rotating gear in the gearbox can be accurately predicted.

Contact us today to find out more about how we can help you manage the challenges of electric drive systems engineering.